WHERE QUALITY

TAKES SHAPE

THE PRODUCTION PROCESSES

Our Production Process Combines Tradition and Sustainable Innovation

Yarns

We select premium raw materials, tested in our in-house laboratory.

Indigo dyeing

A rare expertise in Italy, managed with precision to create vibrant and authentic shades.

In-house weaving room renovated and upgraded to ensure maximum quality and flexibility.

Innovative machinery and eco-technologies such as ozone reduce environmental impact.

Rigorous testing at every stage to ensure consistency and longevity.

A circular production cycle that maximizes every resource and minimizes waste.

YARNS

Extraordinary Raw Materials for Extraordinary Fabrics

Each yarn is chosen to ensure durability, softness, and sustainability, becoming the foundation of denim that lasts and respects the planet.

Because great denim always starts with great yarn.

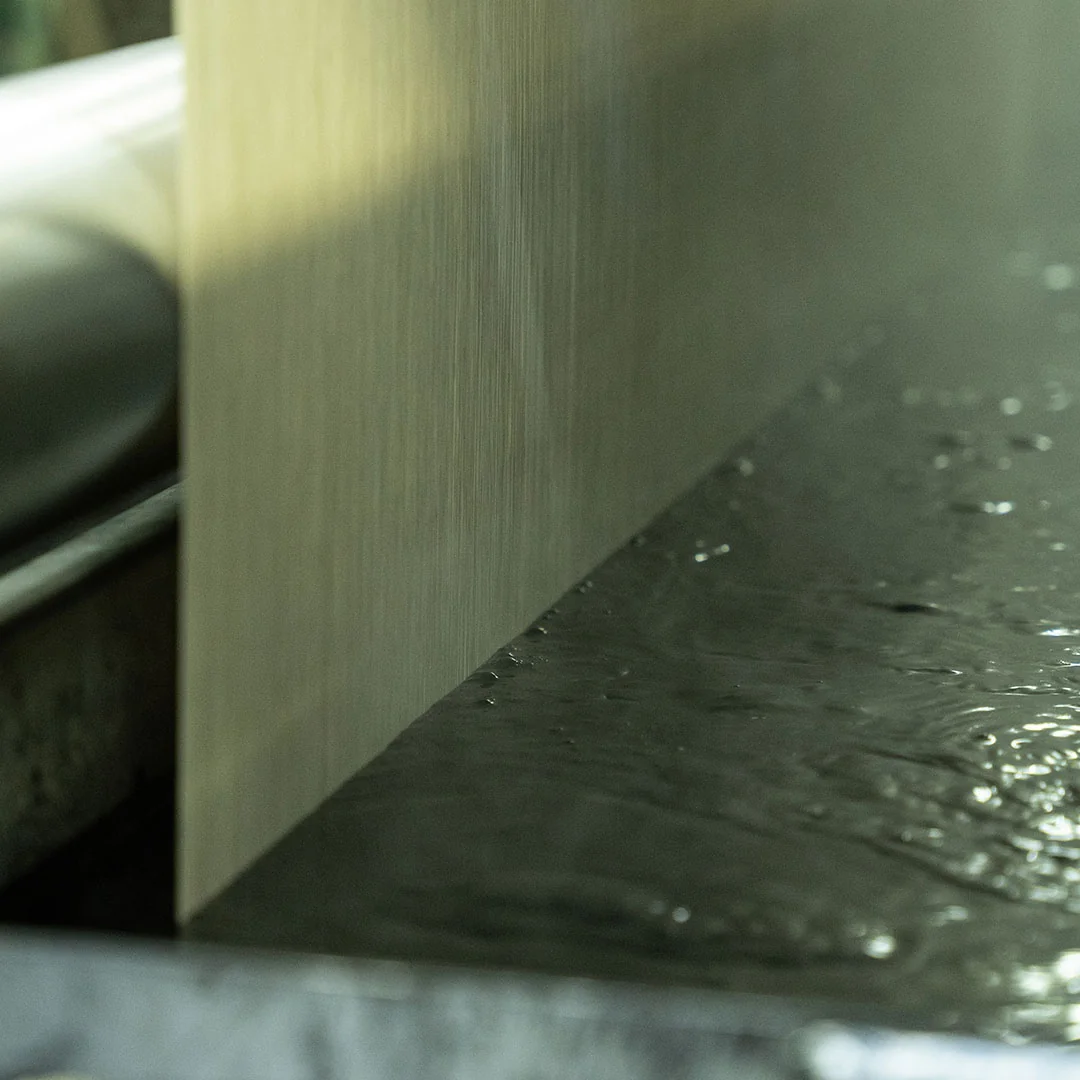

DYEING

Indigo Dyeing: a Rare and Delicate Expertise

In our department, we dye the warp yarn with indigo following a traditional process that is rare in Italy.

A unique and unstable color that requires precision and experience to achieve the right shade.

Its beauty comes from balance: a vibrant, authentic color destined to evolve over time.

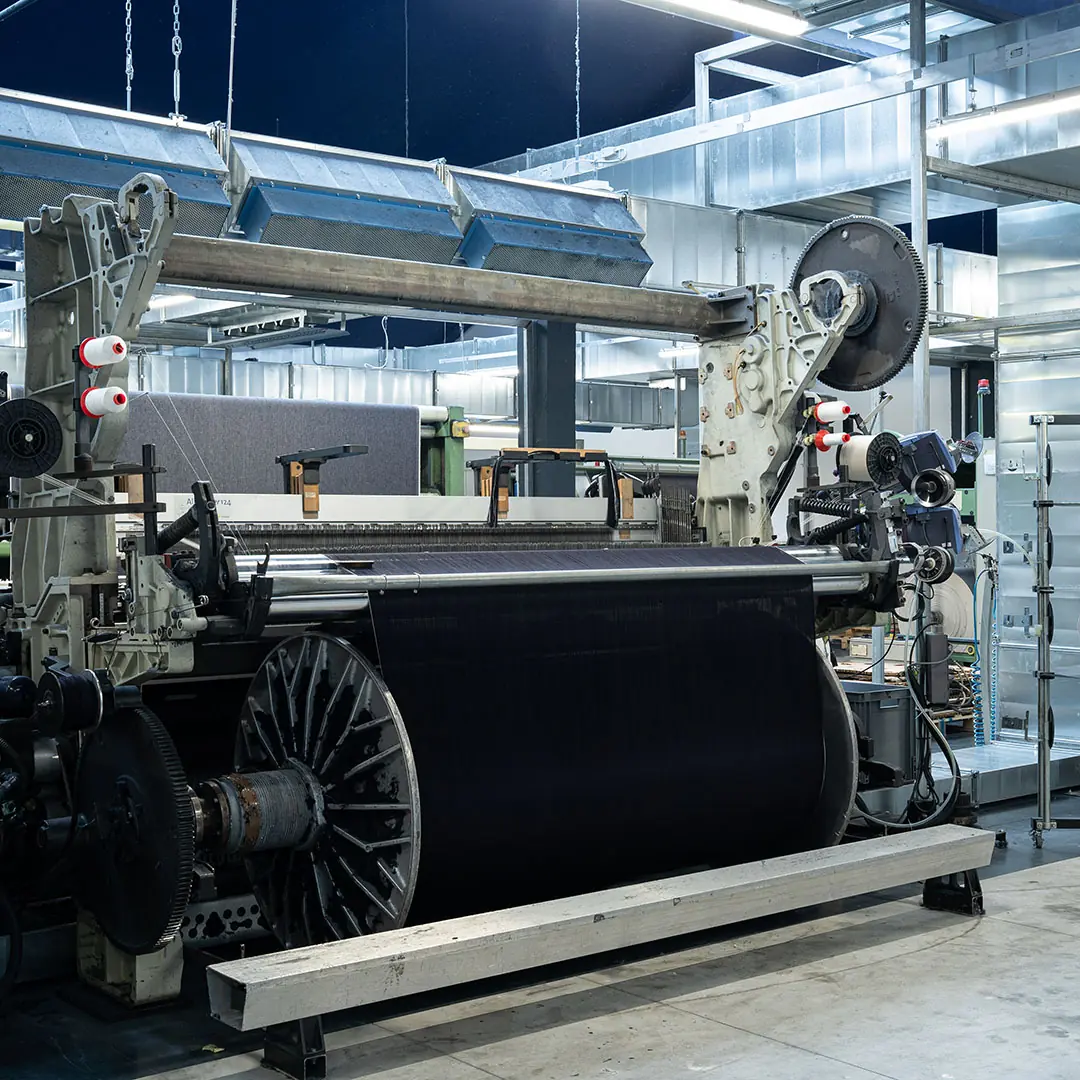

WEAVING

Weaving Room: Compact, Flexible, under Control

Our in-house weaving room ensures speed, flexibility, and attention to customer needs.

We manage samples and control every phase of the process with care and quality.

A lean organization allows us to test, adapt, and innovate while maintaining high technical standards in our fabrics.

FINISHING

Every Detail Makes the Difference

The final phase defines the soul of our denim: softness, durability, water repellency, or vintage effects, thanks to cutting-edge finishing processes.

- Ozone finishing: -85% water consumption and -32% CO₂.

- Matex® Eco Applicator: “dry” chemical applications, without water usage.

- Piece dyeing: for authentic and customized colors

- Prints and applications for exclusive looks

For us, finishing isn’t just a detail: it’s what makes a fabric unique and unforgettable.

QUALITY CONTROL

Consistency, Precision,

Reliability

Every meter of Berto denim undergoes thorough verification.

From visual inspection to laboratory testing, we monitor physical parameters, color fastness, and mechanical performance.

This allows us to guarantee consistent quality over time and offer complete customization, in line with high-end brand and designer requirements.

At Berto, excellence isn’t just controlled: it’s built, every day.